- HOME

- ABOUT

- PRODUCTS

-

-

-

Semi-Customized

-

Full-Customized

-

-

- TECHNOLOGY

- CONTACT

Ceramic Breaks/Isolators

Looking for Ceramic Breaks with

high-performance insulation and airtightness?

Ceramic Breaks, sometimes referred to as "Electrical Isolators" or "Envelopes", consist of metal sleeves brazed to each end of an insulating ceramic tube. Ceramic Breaks are commonly used to introduce fluid/gas into a system and to provide electrical isolation of line components. Our products are used in harsh environments such as high temperature, cryogenic, and high vacuum.

Ceramic Breaks/Isolators (Spiral/Helical Type)

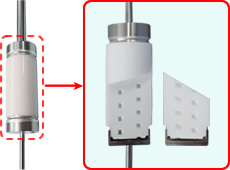

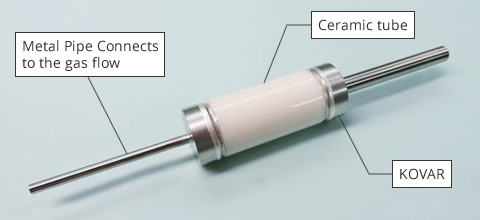

Overview and Basic Structure

The helical ceramic break/isolator is an insulating pipe specifically designed for providing electrical insulation when introducing gases into a system. The spiral flow channel is made of alumina ceramics, ensuring excellent electrical insulation and mechanical strength. KOVAR caps are bonded on both ends to enhance structural integrity and facilitate secure connections. A stainless steel pipe is attached at the tip and is directly connected to the gas flow path. However, for customized applications, the pipe material can be modified to meet specific requirements.

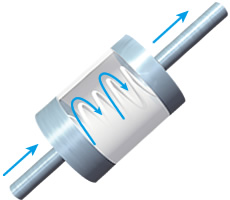

Image of Inner Flow Channel

Cross Section

Ideal for insulating applications in spacecraft propulsion systems

The spiral/helical ceramic break/isolator has a proven track record of being used in spacecraft propulsion systems such as ion thrusters, particularly Hall thrusters, where xenon (Xe) gas is commonly used as the propellant. As a crucial electrical isolator, it ensures reliable insulation in these propulsion systems, which power spacecraft and satellites in orbit.

Enhanced insulation performance in limited space

Despite its compact size, the helical ceramic break provides a long insulation distance in environments where space is severely restricted.

The insulation distance can be increased 2-3 times compared to straight-shaped ceramic breaks/isolators of the same length, making it ideal for spacecraft and satellite applications where every inch of space matters.

Versatile applications

While ideal for use in Hall thrusters and other spacecraft propulsion systems, the helical ceramic break also has proven applications in various semiconductor manufacturing systems, including CVD and sputtering systems, as well as etching/film deposition apparatus. It is particularly used for insulation when introducing process gases.

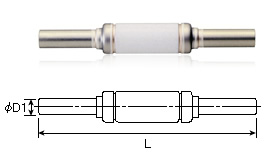

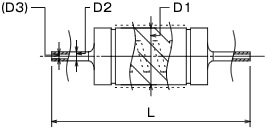

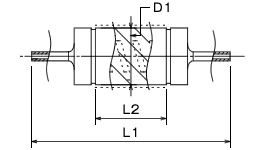

Standard Type

Feature

- Air Tightness: 1.0×10-10Pa·m³/sec

- Length of the inside helical: 190mm

Standard Ceramic Breaks For Gas (Spiral/Helical Type)

Customized Type

If the standard type does not fit, we also provide customization service.

We will create a design to meet your requirements.

Please check the applicable size below.

| Applicable Size (mm) | ||

|---|---|---|

| φD1 | L1 | L2 |

| φ8.5~ | Depends on the length of Ceramic part | Depends on the diameter of Ceramic part |

Ceramic Breaks For Liquid

High Resistance to Leakage and Corrosion :

Specially designed for liquid applications.

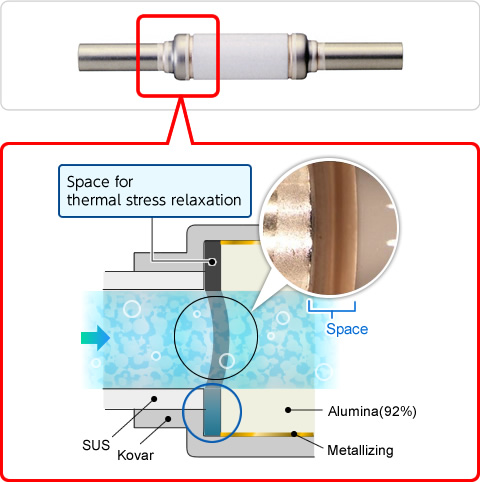

Our Ceramic Breaks(liquid type) are specially designed for the transmission of liquids.

The inside structure is smooth, which can effectively prevent the liquid from staying inside even when the flow stops. (As the Image below)

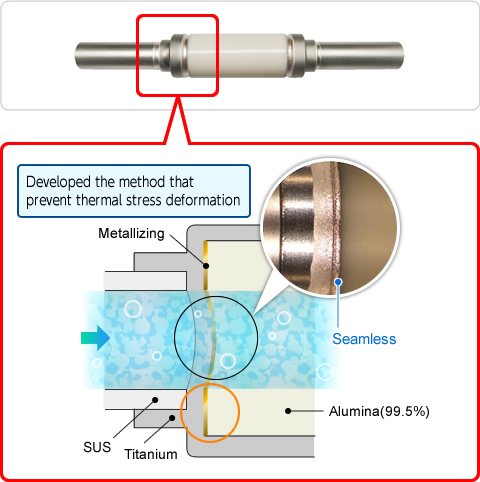

The varying thermal expansion of different materials can cause cracks on the surface of ceramics. To prevent the ceramic parts from cracking, many companies will leave a gap on the joint part to relax the thermal stress.

Instead of leaving a gap on the joint, we created a less susceptible design to thermal stress, and our special brazing technology allows our product to be excellent in corrosion resistance to pure water.

Ceramic Breaks For Gas

Ceramic Breaks For Liquid

Specially designed for the transmission of water and/or coolant fluids

Kawaso Texcel’s metallizing technology is excellent in corrosion resistance to pure water.

Evaluation test on pure water compatibility

Material

Ceramics that are metalized and brazed with Ni-plated metal fittings

Test Condition

pure water at 100°C for 200 hours

Result

Metal elution is not observed on the joint parts.

| Content Level (mg/L) | ||||

|---|---|---|---|---|

| CU | Ag | Ni | Fe | Ti |

| 0.2 | under 0.05 | under 0.05 | under 0.05 | under 0.05 |

Use

- Piping for cooling electromagnets in large-scale accelerators

- Piping for delivering liquid helium

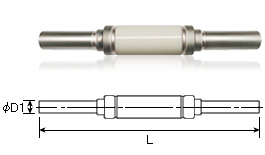

Standard Product

Feature

Insulation resistance(MΩ): over 1,000 (at DC500V), Airtightness: 1×10-10Pa·m³/sec

1,500 Volts

Photo provided by RIKEN

In the field of "Nano Science", our Ceramic Breaks (Liquid Type) are used as an integral part of the cooling equipment of Multipole Vending Electromagnest within Synchrotron radiation facilities in Japan.

Ceramic Breaks For Gas (Straight)

Excellent in airtightness & Corrosion Resistance

Our ceramic breaks can keep high airtightness, even in high temperature/ cryogenic environments.

Also, it is highly corrosion-resistant and is suitable for applications like gas delivery.

Use

- Gas tube for film deposition apparatus

- Gas tube for fuel battery

- Gas tube for cooling apparatus

Standard Product

Feature

Insulation resistance(MΩ): over 1,000 (at DC500V), Airtightness: 1×10-10Pa·m³/sec

1,500 Volts

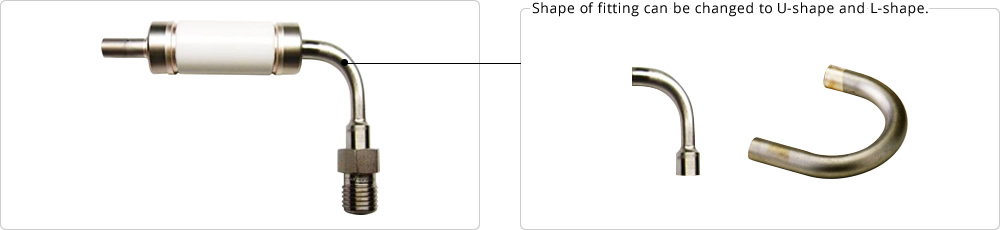

Customized Ceramic Breaks

We design and produce suitable ceramic breaks for your apparatus and equipment.

- By adjusting the shape/material of metal fittings and ceramics, we design the ceramic breaks based on your operating environment and application.

- We can coordinate your requests to change the shape and size of your ceramic breaks to tailor them to your needs.

(extending the creepage distance/provision measures against electrostatic discharge/...) - For the alumina ceramics is In-House made, you can also choose the purity of alumina (92%, 96%, 99%).

Materials

For customized Ceramic Breaks

It is possible to change the material and the shape of fittings(caps/pipes).

| Cap | Kovar | C1020 | Ti | Ni | A1070 | A3003 |

|---|---|---|---|---|---|---|

| Pipe | C1020 / Ti / SUS316 / SUS316L | A1070 | A3003 | |||

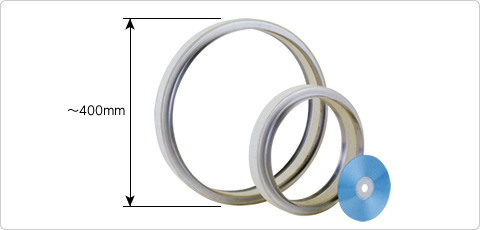

Joint of Aluminium and Alumina

Joining aluminum and alumina ceramics is difficult, because of the gap of thermal expansion of the two materials.

However, our special brazing technology enables the bonding of aluminum and alumina ceramics by developing our unique brazing alloy, by which the airtightness can also be guaranteed.

Shape and Size

MAX dimension 400mm

MAX diameter 400mm

Philosophy

Philosophy Overview

Overview History

History Liquid Cold Plate

Liquid Cold Plate

Insulator

Insulator Melting titanium metallizing

Melting titanium metallizing Research and Development

Research and Development Brazing Technology

Brazing Technology