Copper Type Liquid Cold Plate

We provide brazed copper liquid cold plates making the most of copper's high conductivity.

We design and manufacture liquid cold plates that are optimal for your application and operating environment.

Copper Type Liquid Cold Plate

We provide brazed copper liquid cold plates making the most of copper's high conductivity.

We design and manufacture liquid cold plates that are optimal for your application and operating environment.

Want to know the reason why the brazed Liquid Cold Plates can:

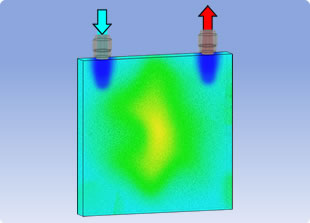

The performance of liquid cold plates varies greatly depending on the flow path and the accuracy of the contact surface with the heat source even if the material and pump capacity are the same.

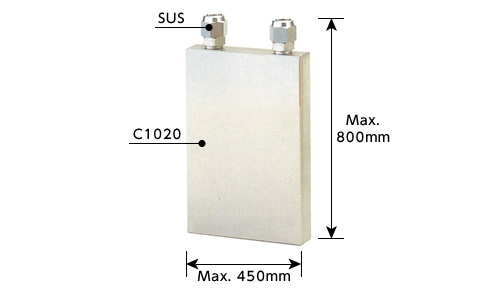

| Material | Body | C1020 (oxygen-free copper) |

|---|---|---|

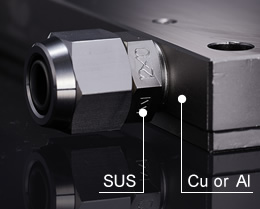

| Mouthpiece | SUS | |

| The maximum size | 800L × 450W | |

| Flatness | 0.02mm or less (cooling section) | |

| Parallelism | 0.02mm or less (cooling section) | |

| Surface treatment | Ni plating | |

Oxygen-free copper can be used even in vacuum apparatus because its gas release is minimal.

We recommend Ni plating to protect the cooling performance from oxide and prevent further corrosion on the surface.

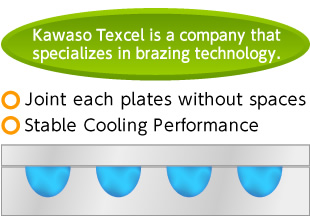

We use our brazing technology to join the main body side & the lid, and the body & the fitting. This process is highly reliable and environment-friendly as it does not use flux.

* If you have any questions about Chillers, Teflon tube or grease, please feel free to contact us.

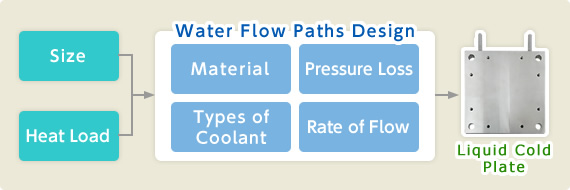

If you inform us of the dimensions and heat load of your device, we design and suggest an appropriate type of a liquid cold plate to meet your specific requirements.

We recommend stainless steel fittings, which have high corrosion resistance and heat resistance.

As stainless steel fittings are joined with copper or aluminum plates by our advanced brazing technology, we guarantee the reliable and long-term use of our products.

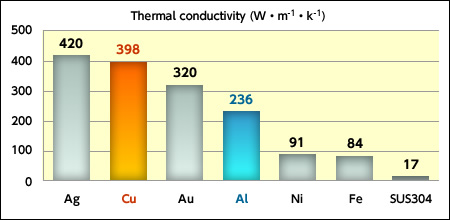

The thermal conductivity of copper (398W · m-1 · k-1) is the second to highest, following silver (420W · m-1 · k-1), twice that of aluminum (236W · m-1 · k-1), and 20 times higher than that of stainless steel (16.7W · m-1 · k-1). Therefore, copper is suitable for liquid cold plates.

We have a laboratory in our factory to test the performance of liquid cold plates under various conditions.

You can utilize our laboratory to make sure of the performance of your products. more

| Characteristic | Copper | Aluminum | Stainless |

|---|---|---|---|

| Thermal conductivity |

398 | 236 | 17 |

| Specific gravity | 8.82 | 2.68 | 7.93 |

| Corrosion resistance |

◯ | △ | ◎ |

We design and manufacture the optimum liquid cold plate with material to meet your application and operating environment, such as copper with excellent heat dissipation, aluminum with excellent weight saving, stainless steel with strong corrosion resistance.

Please feel free to contact us for chillers, piping, Teflon tubes, grease, and thermal conduction sheets.

The product's material can determine what type of coolants to use in the liquid cold plate.

We will suggest the optimum combination of the plate's material and coolant according to your requests and operating environment.