Metallized & Brazed Product

- HOME

- ABOUT

- PRODUCTS

-

-

-

Semi-Customized

-

Full-Customized

-

-

- TECHNOLOGY

- CONTACT

Metallized & Brazed Product

Brazing metallized ceramics and metal, we achieves highly airtight joints (1 × 10-10 Pa · m3 / s or less).

Metallizing is the formation of a metal film on a non-metal surface.

Kovar is often used as the metal to be joined because it has a coefficient of thermal expansion close to that of ceramics,

But, as shown in the table below, it is also possible to join with various metals.

Laboratory and University

Our products manufactured by our "Melting Titanium Metallizing" are used in various industries for many years of reliability and achievement.

Through joining technology, we support the facilities and equipment that from the basis of people's lives in the world.

We verify whether each product has the joining characteristics that satisfy the required performance, such as leak resistance, withstand voltage, insulation resistance, pressure resistance, etc.

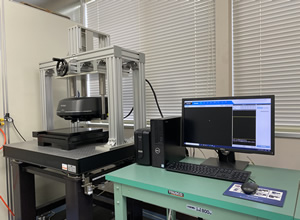

Shape Measurement Laser Microscope

It is used for high-precision observation of fine shapes.

It is used for high-precision observation of fine shapes.

The fine uneven shape and roughness of the surface are observed on the nano-order, and the measured fine uneven shape is visualized by gradation.

The maximum observation magnification is 2,800 times.

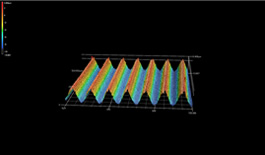

3D Scanner CMM Controller

This is an equipment that measures 3D shapes.

This is an equipment that measures 3D shapes.

The measured 3D shape can be visualized by gradation.

In addition, we do a quantitative evaluation of which part and how much the shape difference occurs by comparing it with the 3D CAD diagram.

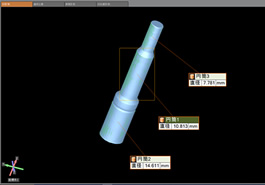

Image Dimension Measurement System

It is used for dimensional measurement of incoming inspection and outgoing inspection.

It is used for dimensional measurement of incoming inspection and outgoing inspection.

In addition to dimensions such as circles, lengths, and steps, it is possible to measure geometric tolerances such as parallelism, roundness, squareness, and coaxiality.

And, the process capability index and measurement results are monitored with a trend graph from the measurement history.

X-ray Non-destructive

Inspection Equipment

This equipment is used for fluoroscopy of joints at high magnification by non-destructive.

This equipment is used for fluoroscopy of joints at high magnification by non-destructive.

We are observing the amount of the brazing material, the voids, the fillet and the internal condition that cannot be confirmed from the outside.

Withstand Voltage Tester

We inspect the withstand voltage characteristics of our products.

We inspect the withstand voltage characteristics of our products.

It is possible to evaluate the withstand voltage characteristics by the voltage value according to customer's request.

In addition, tests in vacuum environment are also possible.

Helium Leakage Tester

We inspect the airtightness of joints (metallized and brazed parts) or welded joints.

Normally, we do test to evaluate the amount of helium leak with

1 × 10-10 Pa · m3 / sec or less.