Liquid Cold Plate

Maximize the performance of UV-LEDs and Power modules

Liquid Cold Plates provide an effective thermal solution for your devices with a high heat load, such as IGBT and UV-LED.

Liquid Cold Plate

Maximize the performance of UV-LEDs and Power modules

Liquid Cold Plates provide an effective thermal solution for your devices with a high heat load, such as IGBT and UV-LED.

Want to know the reason why the brazed Liquid Cold Plates can:

Liquid cold plates, also known as water/liquid-cooled heat sinks, are the most efficient method of heat removal. By circulating a liquid coolant through its internal channels, it absorbs the heat from the device and transfers it to the coolant, which temperature is ideally controlled by a chiller.

With over 20 years of experience in designing and producing the liquid cold plate, our products minimize the variation of surface temperature and achieve “Uniform Cooling”, and with a reliable brazing method to guarantee the airtightness with no water leak.

Achieve cooling performance by making full use of various tools!

We cooperate from trial production and solve your problem!

*Please also consult with us about peripheral equipment such as chillers.

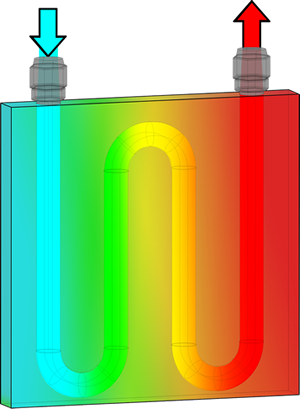

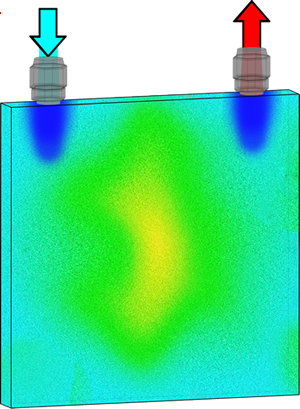

The surface temperature of the liquid cold plate tends to vary near the inflow and outflow points, due to the coolant absorbing the heat.

Uneven cooling can influence the performance of the device. Therefore, it is vital to design an optimized flow path to reduce surface temperature fluctuations.

We have a great deal of experience and skill in designing the optimal flow path to provide uniform cooling to the device.

General design

In a general flow path design shaped like the letter “M”, the surface temperature tends to vary near the inflow and outflow points.

Our design

Our liquid cold plates are designed with an optimized flow path, making it possible to cool the whole surface uniformly.

Standard |

Aluminum |

Copper |

For IGBT |

Thin Multi-Layer |

|---|---|---|---|---|

Customize |

Semi-Customized | |||

Universal |

||||

| Full-Customized | ||||

Aluminum |

Copper |

Stainless Steel |

For UV-LED |

|

If you are considering a liquid-cooling solution for your devices, we recommend choosing from our Standard Series and Semi-customized Series for a shorter lead time.

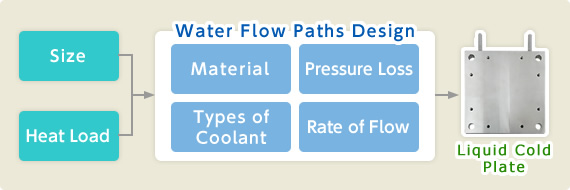

For customization, we need information such as the size and heat load of your device for the first step.

We will design and suggest the liquid cold plate strictly based on your requirements.

In order to remove the heat from device, it is important to be fully contacted between the surface of the liquid cold plate and the device.

We guarantee that the surface flatness of our liquid cold pate is 0.02mm or less to be able to make perfect contact with device.

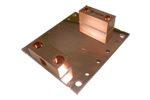

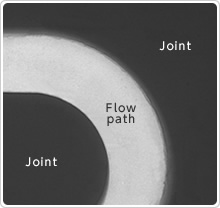

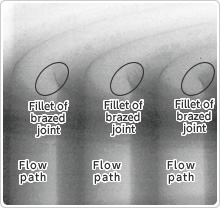

The liquid cold plate is perfectly joined by our advanced brazing technology.

We guaranteed airtightness with no water leak.

The plate is perfectly joined by our advanced brazing technology.

We guaranteed water tightness with no leak.

Imperfect brazing caused water leak and corrosion.

We’ve never had water leak problem since we‘ve started sales for 20 years

Confirmation example of joints by X-ray transmission device

Plating treatment improves corrosion resistance of liquid cold plate.

We have our own plating equipment in our factory for continuous process with plating to avoid the transport damage.

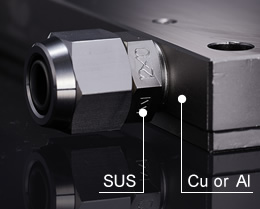

We recommend stainless steel fittings, which have high corrosion resistance and heat resistance.

As stainless steel fittings are joined with copper or aluminum plates by our advanced brazing technology, we guarantee the reliable and long-term use of our products.

We have a laboratory in our factory to test the performance of liquid cold plates under various conditions.

You can utilize our laboratory to make sure of the performance of your products. more

| Characteristic | Copper | Aluminum | Stainless |

|---|---|---|---|

| Thermal conductivity |

398 | 236 | 17 |

| Specific gravity | 8.82 | 2.68 | 7.93 |

| Corrosion resistance |

◯ | △ | ◎ |

We design and manufacture the optimum liquid cold plate with materials to meet your application and operating environment.

You can choose from:

Copper with excellent heat dissipation, Aluminum with excellent weight saving, Stainless steel with strong corrosion resistance.

If you have any questions about using the liquid cold plates and liquid cooling devices, please feel free to contact us for more information.

The product's material can determine what type of coolants to use in the liquid cold plate.

We will suggest the optimum combination of the plate's material and coolant according to your requests and operating environment.