UV-LED Liquid Cold Plate

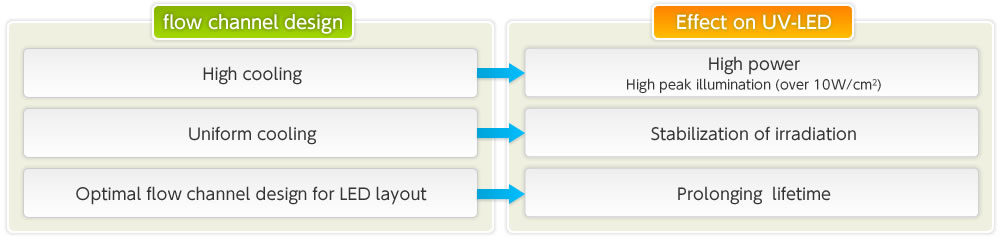

Uniform irradiation and brightness are required for UV-LED lighting.

We design a uniform cooling flow path exclusively for UV-LEDs. It evenly cools the LED device at once, and thus achieves uniform irradiation and brightness.

Want to know the reason why the brazed Liquid Cold Plates can:

- Reduce more temperature

- Achieve uniform cooling

Uniform cooling flow path design made uniform irradiation possible

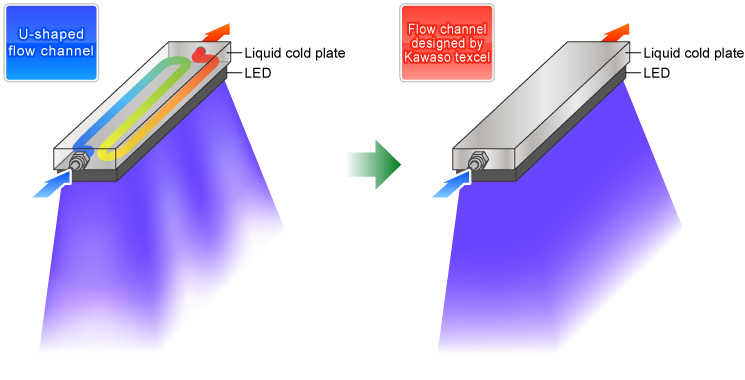

Problem

A general flow path generates temperature variation on the surface of a liquid cold plate.

In other words, general liquid cold plates cause fluctuation in UV LED irradiation amount, and this would affect the product quality of the irradiated body.

Solution

Uniform cooling of heat sink surface reduces fluctuations in the amount of UV irradiation and enables efficient irradiation of the irradiated object.

We have much experience and skill in designing the best flow path to provide uniform cooling.

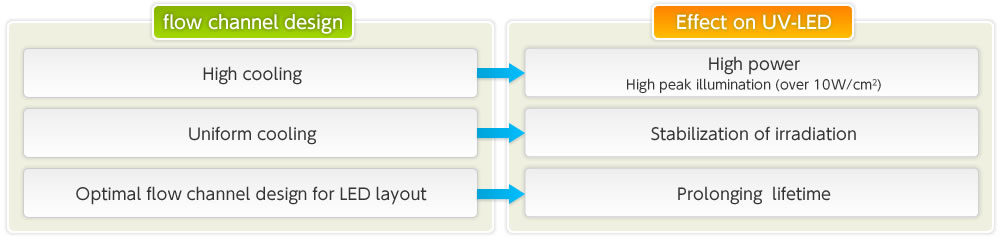

Feature

Want to raise more light output ?

- For customers looking for high power LEDs, we design and provide the optimum liquid cold plate perfect for your operating environment.

- Our uniform cooling technology supports high power LED lighting, uniform irradiation and extended product lifespan.

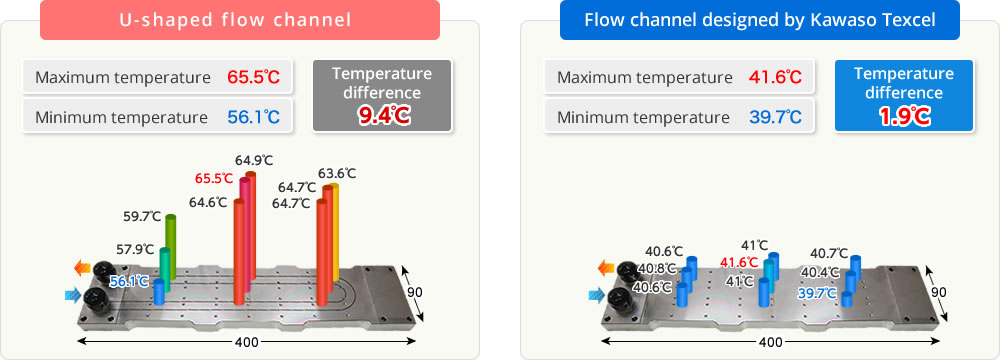

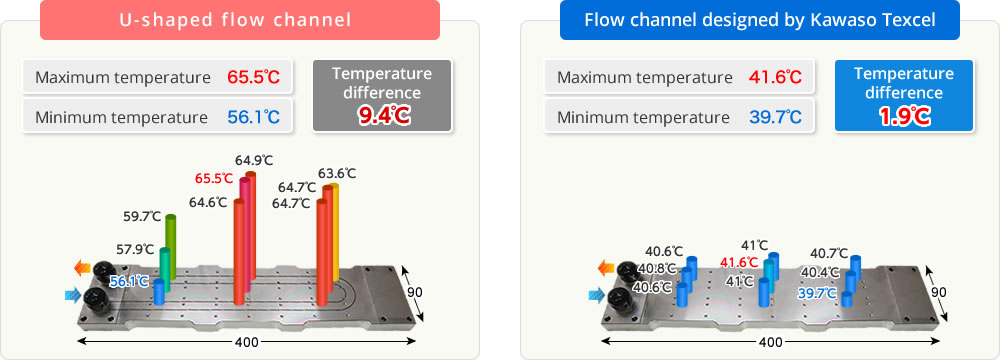

Comparison of temperature distribution in

a uniform flow path and a general flow path

| Test Condition |

| Materials |

Size |

Thermal load |

Refrigerant |

Refrigerant temperature |

Flow rate |

| Copper(C1020) with Ni plating |

400×90×19t |

2000W |

Ethylene glycol |

30°C |

5L/min |

* Material: C1020(Oxygen-free Copper), surface nickel-plated

* Flow Path: Width 12mm × Depth 10mm

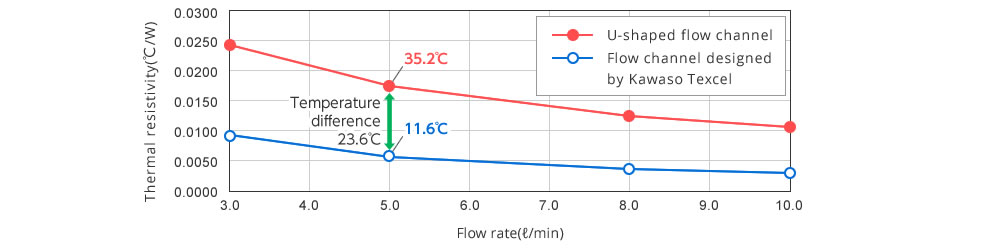

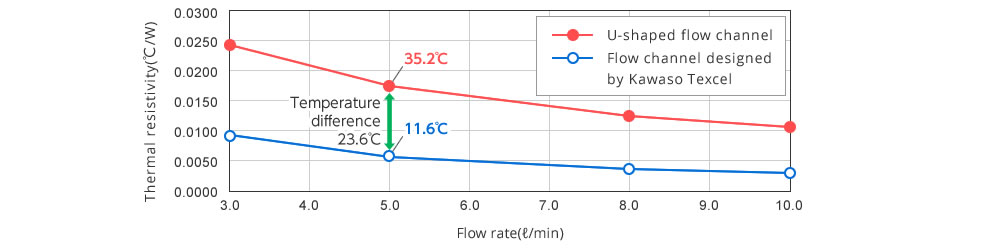

Comparison of thermal resistivity

We design and provide optimum liquid cold plates that suit your application and operating environment.

Uniform cooling supports the high-power LED output, uniform irradiation and long product lifespan.

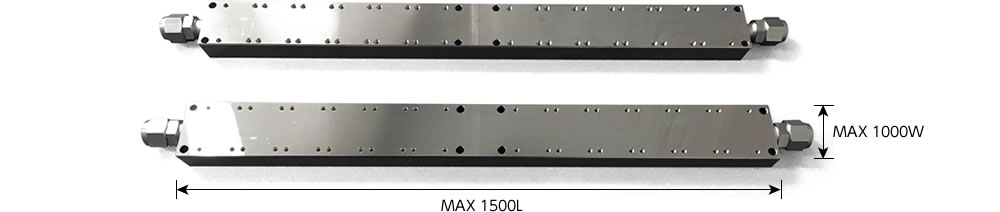

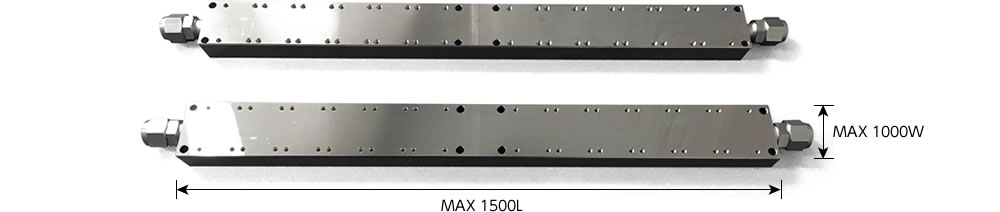

Size

Up to size 1500L × 1000W

Surface treatment

Optimal surface treatments for your application and operating environment.

| Treatment |

Purpose |

| Backing Finish |

Prevention matte baking refrection. |

| Electrodeposition coating |

Electrodeposition coating heat dissipation improvement. |

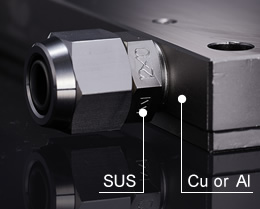

Fitting connection

We recommend stainless steel fittings, which have high corrosion resistance and heat resistance.

As stainless steel fittings are joined with copper or aluminum plates by our advanced brazing technology, we guarantee the reliable and long-term use of our products.

Laboratory

Laboratory to check the performance of your liquid cold plate!

We have a laboratory in our factory to test the performance of liquid cold plates under various conditions.

You can utilize our laboratory to make sure of the performance of your products. more

Coolant

The product's material can determine what type of coolants to use in the liquid cold plate.

We will suggest the optimum combination of the plate's material and coolant according to your requests and operating environment.

- Copper

-

- Pure water (managed by ion exchange unit)

- Industrial water, tap water (neutral, requires management of pH)

- Antifreeze (with rust inhibitor)

Ethylene glycol + pure water

Propylene glycol + pure water

- Aluminum

-

- Pure water (managed by ion exchange unit)

- Antifreeze (with rust inhibitor)

Ethylene glycol + pure water

Propylene glycol + pure water

- Stainless

-

- All kinds of coolants are available.

* Pure water, Industrial water, City water and Antifreeze

Liquid Cold Plate Line up

Philosophy

Philosophy Overview

Overview History

History Liquid Cold Plate

Liquid Cold Plate

Insulator

Insulator Melting titanium metallizing

Melting titanium metallizing Research and Development

Research and Development Brazing Technology

Brazing Technology