Melting Titanium Metallizing

This technology achieves high airtightness and long-term reliability.

Melting Titanium Metallizing

This technology achieves high airtightness and long-term reliability.

We created our special metallizing technology to utilize the reaction of melted titanium developed independently. It is called "melting titanium metallization technology"

We developed this technology to better join ceramics, nonmetallic materials, and/or metal materials, all of which have poor bonding properties due to their different crystal structures.

To join them airtightly and firmly, we need to metallize the surfaces of ceramics or nonmetallic materials and to generate a bonding between metal materials.

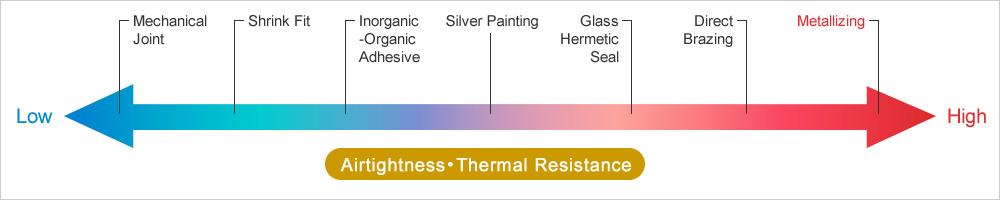

This method of joining the surface of ceramics or nonmetallic materials is called "Metallizin"". This process is significant as how you join metal greatly affects its bondability.

| Materials | Use | ||

|---|---|---|---|

| Nonmetal | Metal | ||

| Al2O3 | Kovar | Ceramic tube for water cooled | |

| Kovar | Power feed through Vacuum envelopes Insulator |

more | |

| SUS304, Ti | |||

| Al, Cu | |||

| Sapphire | SUS304, SUS316, Kovar | Ultra-high Vacuum Viewing Port | more |

| AlN・Si3N4 | Cu | Insulator | |

| Si・Ge, SiO2, Diamond | Kovar, Mo, W | Transmission window | more |

Brazing process with ceramic and metal

The Melting titanium metallization, our unique metallizing technology works as follows:

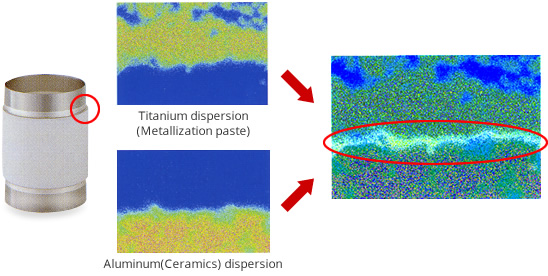

First, we create metal layers on the surface of ceramics by applying the titanium-based metal paste on the surface of ceramics and processing them in a high-temperature vacuum condition to bring out reactions from the composition of the two.

After the metallization, we conduct the plating process and bond Kovar(an Fe-Ni-Co alloy) and Fe-Ni alloy by brazing (BAg-8 mainly). We guarantee the following: 1.3×10-10Pa·m³/sec in the amount of helium gas leak for the more reliable gas-tight joint.

This metallization method is also different from the “direct brazing method”, which inserts the active metal brazing material between the ceramic and the joining material and then bonds them by one-time heat treatment.

The melting titanium metallization method has the following features.

The above two photos show the ceramic distribution of metallizing connections and the titanium distribution of metallizing paste. Overlapping these two photos, you can confirm that titanium firmly and accurately diffuses into the ceramic.